Boiler and softener maintenance : how this professional optimizes controls

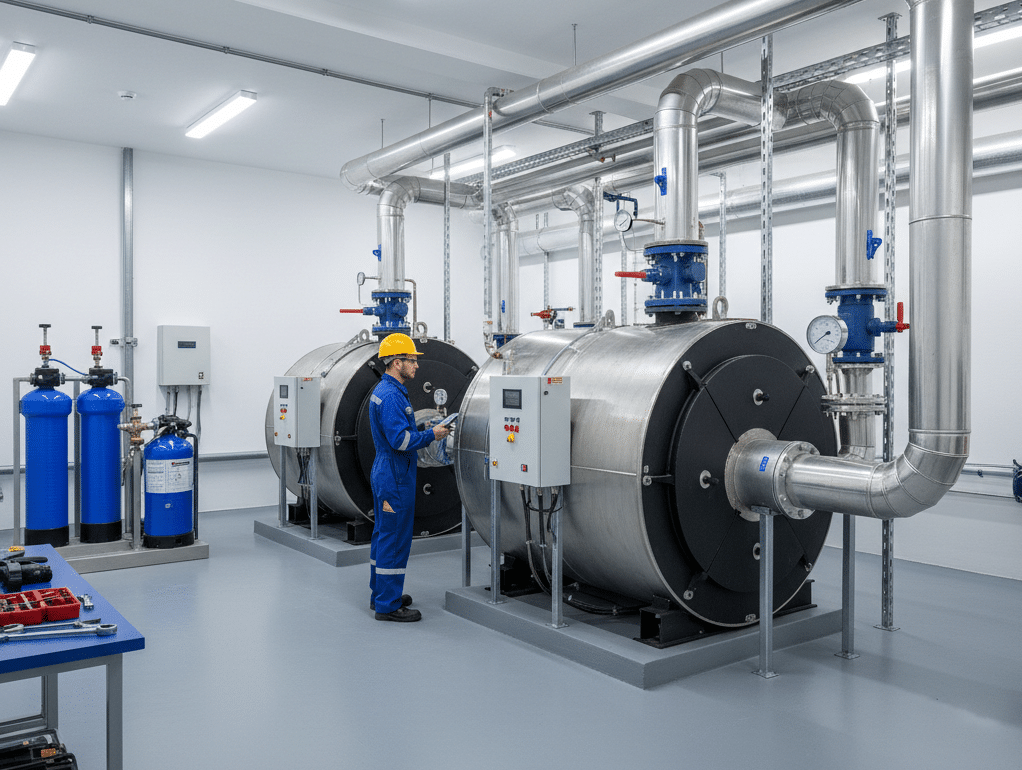

Context and objective – water monitoring in boiler systems

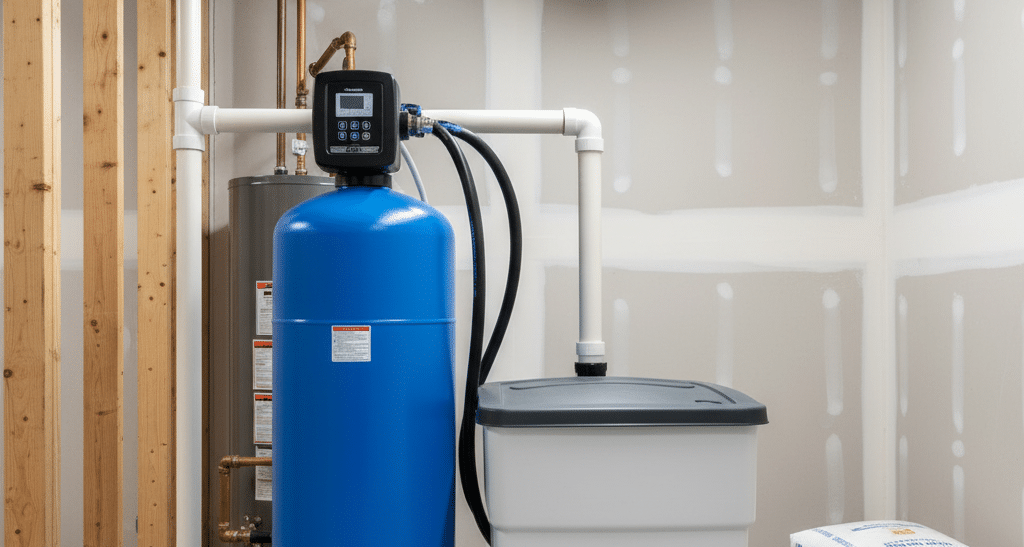

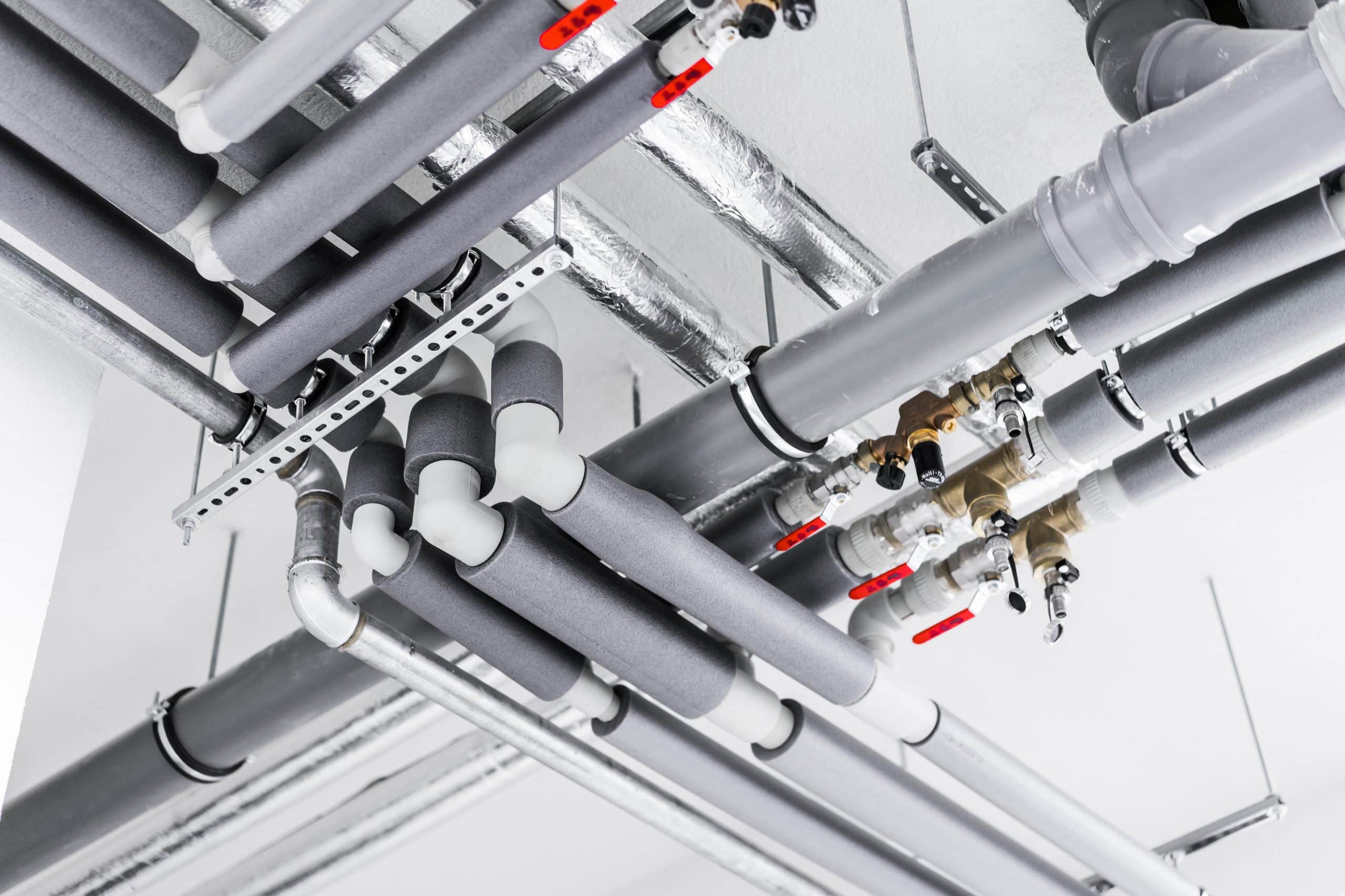

In collective heating installations, water quality is crucial to preserve performance and prevent premature wear of equipment. An imbalance in parameters such as hardness or pH can cause scaling and corrosion. This is why regular water monitoring is essential, especially during boiler and softener maintenance.

A specialized maintenance company chose to simplify its interventions thanks to Aqualabo kits. The goal was to shorten intervention time, allow autonomous work, and still ensure reliable, high-quality monitoring.

This case study describes a maintenance operation in a small residential building on the outskirts of Paris.

Project details – boiler and softener maintenance

The project

Based in Île-de-France, our client works as a subcontractor for several heating companies, maintaining installations for their customers. During an annual inspection in a residential building, the company was responsible for checking the state of the condensing boiler, analyzing circuit water quality, ensuring the proper functioning of the softener, and cleaning the magnetic filter retaining metallic oxides.

Aqualabo solutions

After previously using more complex equipment, not well-suited to routine interventions, our client simplified their analysis method. They now monitor four essential parameters:

- pH and sulfites with colorimetric test strips

- Total hardness (TH) and chlorides with analysis kits

Solutions used:

- Total hardness kit, 3 bottles (ref. 1KT001)

- Chloride kit (ref. 1KC020)

- pH test strips 4.5–10 (ref. 1PI120)

- Sulfite test strips 0–1000 mg/L (ref. 1PI306)

This simplified method enables quick diagnosis and saves time on-site, without cumbersome equipment. At the end of the maintenance, results are recorded in the monitoring log to ensure compliant water quality at the boiler inlet.

Kits and reagents for plumbers and installers

What are kits and reagents used for in closed-loop water analysis?

In routine interventions, plumbers and installers need to measure key water indicators within equipment. Kits and reagents are very easy to use and allow compliance to be checked in just a few minutes: hardness, pH balance, chloride or sulfite levels… These checks help keep installations in good condition over the long term.

Which parameters are essential to monitor for equipment durability?

To ensure long-term performance, several parameters must be monitored regularly:

- pH: reflects the acid-base balance of water. A low pH promotes metal corrosion, while a high pH can cause scaling and reduce treatment efficiency.

- Total hardness (TH): linked to calcium and magnesium content, influencing scale formation. Monitoring helps optimize softener settings and prevent limescale buildup.

- Chlorides: excessive levels accelerate corrosion, especially in stainless steel systems. Monitoring is vital to protect surfaces and avoid costly repairs.

- Sulfites: used as oxidation inhibitors in certain circuits. Their concentration must be checked: too low reduces protection against corrosion, while too high may affect other water parameters.

These indicators help professionals diagnose quickly and adjust treatments when necessary.

AQUALABO kits and reagents

Aqualabo offers a complete range of kits and reagents, designed for plumbers, installers, and maintenance technicians. They deliver immediate, clear results with no special training required. Portable and easy to use, the kits are ideal for on-site interventions: softener checks, network water monitoring, or post-installation verification.

All our kits are developed and assembled in France to ensure consistent quality, full traceability, and precise responses to professional needs.