Analyse de l’eau de chaudière : guide complet

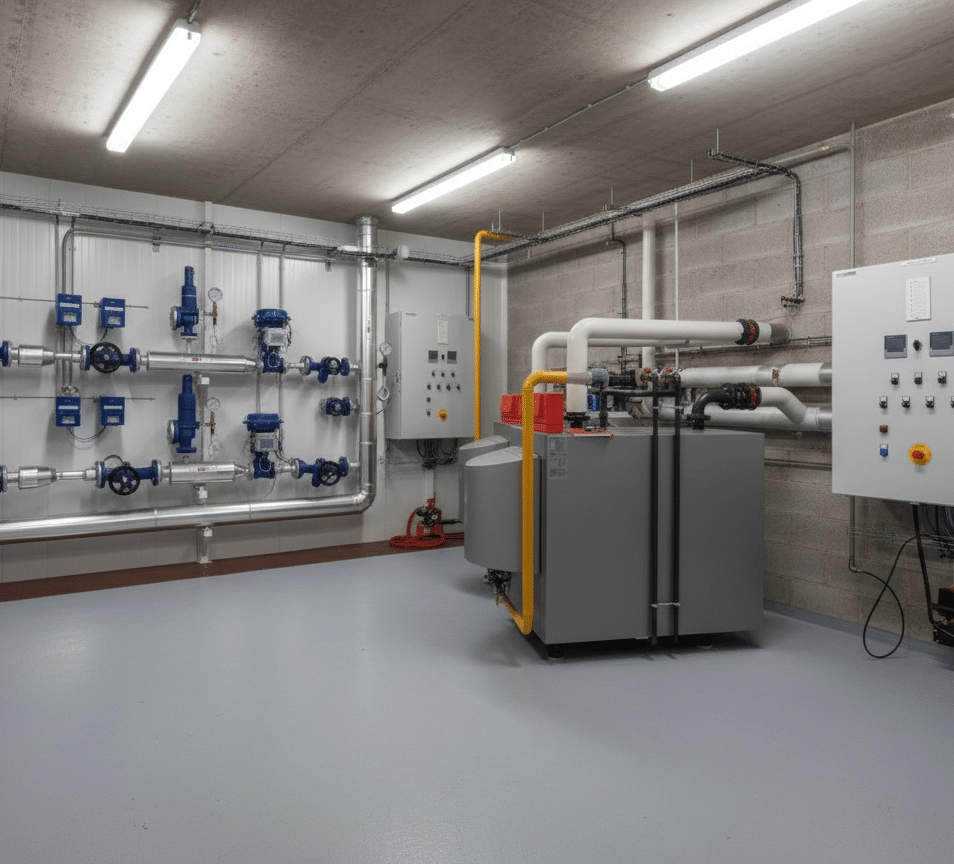

In boiler rooms, water quality directly determines how the thermal circuit operates. Water composition affects heat transfer, hydraulic stability, and equipment lifespan. A physico-chemical imbalance, even a gradual one, can lead to corrosion, deposits, or pH drift, with consequences for boiler efficiency and reliability.

Boiler water analysis helps identify these deviations and ensures accurate monitoring of circuit parameters. This guide covers the fundamentals of boiler room water testing: the chemical mechanisms to control, the parameters to monitor, relevant sampling points, and analytical methods suited to on-site maintenance operations.

Understanding why boiler room water analysis matters

In boiler rooms, water circulates continuously under high temperature and pressure. It is exposed to complex physico-chemical phenomena that evolve with how the system operates. Without regular monitoring, these changes can remain invisible until major malfunctions occur.

Water analyses make it possible to verify the circuit’s chemical balance, assess the effectiveness of treatment programs, and anticipate drift before it affects boiler performance. This is part of a preventive maintenance approach, essential to ensure system stability and durability.

Why water is a key factor in efficiency

Water is the boiler’s heat-transfer fluid. Its composition directly affects heat exchange quality. Even small amounts of deposits on heat-transfer surfaces limit thermal transfer. This leads to higher wall temperatures, a gradual loss of efficiency, and increased fuel consumption.

Direct impacts on equipment lifespan

Corrosion and scaling are among the main causes of degradation in boilers and associated networks. Corrosion progressively weakens metal walls, while scale reduces the effective cross-section of pipes and heat exchangers.

These phenomena cause premature wear, leak risks, and high maintenance costs. Water analysis enables treatment adjustments before damage becomes irreversible.

The role of field professionals in boiler water analysis

Maintenance technicians, installers, and plumbers play a direct role in monitoring boiler room water quality. They take samples at strategic points in the circuit, perform on-site analyses, and interpret results to anticipate or correct potential imbalances. With methods adapted to field constraints, these professionals can track key parameters over time, verify circuit stability, and ensure the long-term operation of the boiler room.

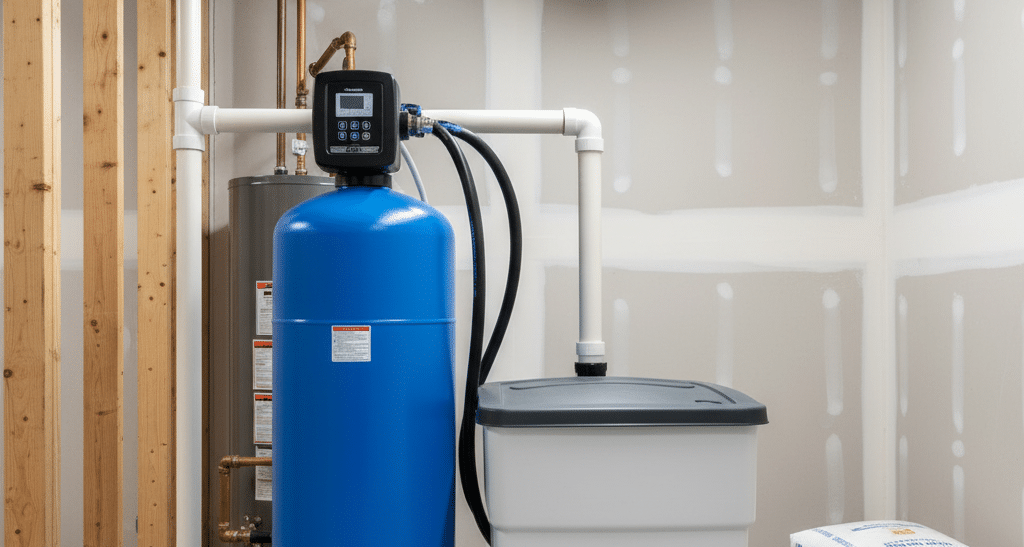

This approach is illustrated in the field through a boiler room and water softener maintenance intervention carried out by a heating professional, highlighting the use of simplified on-site testing methods.

Understanding the chemical behavior of boiler room water

Before interpreting analysis results, it is essential to understand how water behaves chemically in a boiler room. Under the combined effects of temperature, pressure, and heat exchange, water’s physico-chemical balance changes continuously. These transformations explain phenomena such as corrosion, scaling, pH drift, or condensate degradation. Reading parameters in isolation is not sufficient: only an understanding of the mechanisms allows analyses to be interpreted correctly.

CO₂ and bicarbonate behavior in boilers

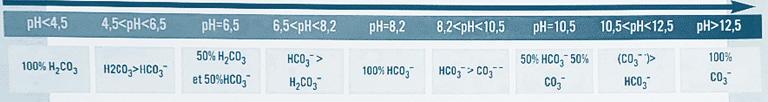

Carbon dioxide plays a central role in boiler room water chemistry. In solution, CO₂ dissolves as carbonic acid (H₂CO₃), according to an equilibrium that depends on pH. In boilers, under temperatures above 60°C and pressure, bicarbonates (HCO₃⁻) partially decompose into carbon dioxide and hydroxide ions (OH⁻). CO₂ is then carried with the steam, while hydroxide ions react with bicarbonates to form carbonates (CO₃²⁻).

pH evolution and consequences for materials

Carbonate formation in boilers causes pH to increase, generally stabilizing above 10.5. Conversely, CO₂ released into steam dissolves again in condensate, giving it an acidic character. This acidity explains the need to treat condensate using neutralizing amines. CO₂-related corrosion results in a uniform attack on steel, causing progressive, homogeneous thinning of metal walls, comparable to chemical abrasion.

Acid gases, degassing, and make-up water treatment

The presence of acid gases in heating networks requires degassing operations and neutralization of water using appropriate bases. These phenomena highlight the value of demineralizing or decarbonating make-up water. Less mineralized water reduces steam-treatment needs and lowers corrosion risks in condensate networks, while improving overall circuit stability.

Interpreting pH in boiler rooms relies on alkalinity parameters. Partial alkalinity corresponds to the concentration of strong bases, mainly hydroxide and carbonate ions, maintaining pH above 8.2. Total alkalinity includes these bases as well as salts of weak acids, such as bicarbonates or certain phosphates, and maintains pH above 4.5. Total alkalinity therefore encompasses partial alkalinity and is a global indicator of water’s buffering capacity.

Total hardness (TH) represents the sum of calcium and magnesium concentrations. In the presence of carbonates and at temperatures above 60°C, these ions become insoluble and precipitate as scale (CaCO₃ or MgCO₃). As an indication, 1 °f of total hardness can generate up to 10 g of scale per cubic meter of make-up water. In domestic hot water systems, scaling risk generally remains limited due to low make-up water volume, while corrosion remains the main issue.

Dissolved oxygen and rapid corrosion mechanisms

Dissolved oxygen is the main catalyst for iron corrosion in boiler rooms. Unlike CO₂-related corrosion, it manifests as localized pitting attacks that can be particularly rapid. Although rarely included in routine analyses, this parameter deserves special attention, especially on feedwater downstream of pumps that may draw in air. Dissolved oxygen concentration decreases sharply with temperature, from around 12 mg/L at 15°C to less than 20 µg/L at 105°C. Maintaining feedwater above 60°C promotes partial degassing and reduces the need for chemical oxygen scavengers.

Condensate quality and detection of carryover

Steam and condensate quality directly reflect the effectiveness of water treatment and boiler operation. Carryover, corresponding to boiler water being entrained in the steam, can be detected by measuring conductivity or by checking for traces of chlorides in condensate, notably by titration (silver nitrate or mercuric nitrate methods). These checks help identify malfunctions quickly and adjust operating parameters.

Recommended frequency and sampling points

Recommended testing frequency

Testing frequency depends on boiler type, the volume of circulating water, and operating constraints. Some parameters must be checked daily, while others can be monitored weekly or monthly.

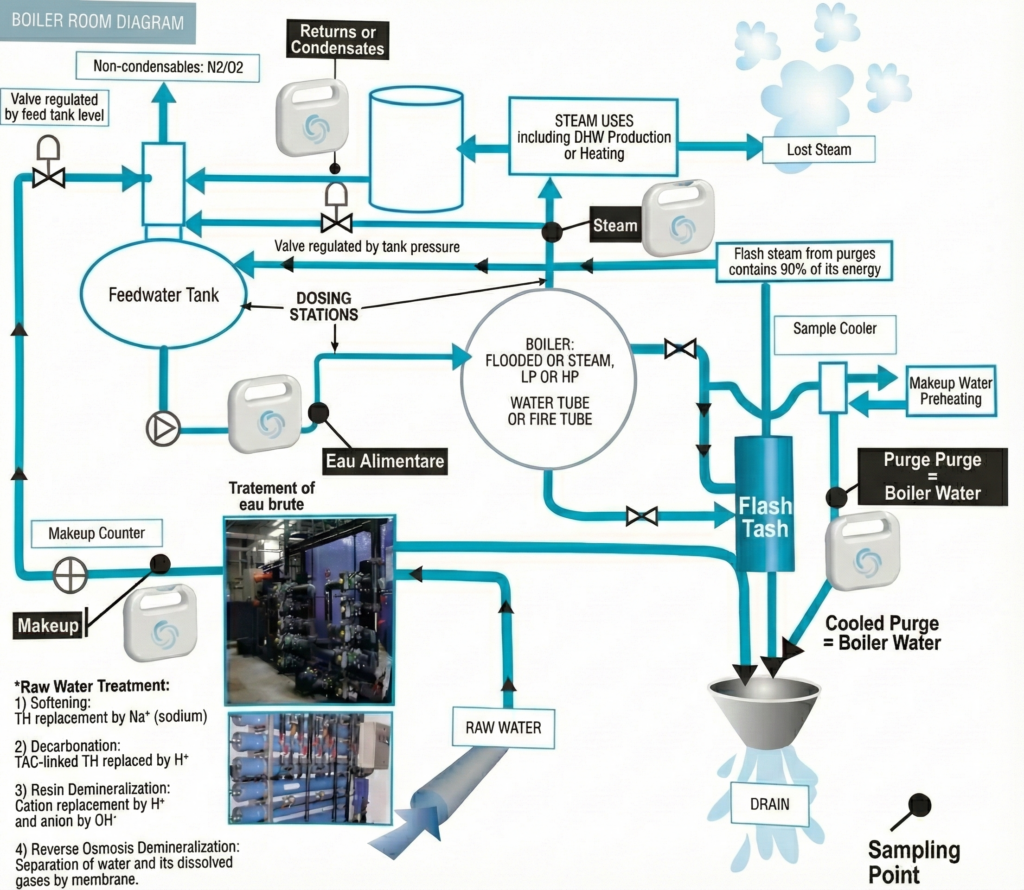

Sampling points in boiler rooms

To obtain representative results, samples must be taken at key points in the circuit: make-up water, feedwater, boiler water, blowdown, steam, and condensate returns.

Each sampling point provides specific information about circuit condition and treatment effectiveness. Proper sampling location is essential to interpret analysis results accurately.

Cooling system water analysis diagram | AQUALABO

Our solutions for boiler room water analysis

To enable maintenance technicians and operators to perform reliable monitoring directly on site, Aqualabo offers a complete range of bench-top analysis solutions for boiler rooms. The Aqualabo solutions presented here illustrate the main analytical methods used in boiler rooms. For an approach dedicated to operational maintenance and simplified controls, specific pages detail these systems.

Volumetric titration analyses: the foundation of boiler monitoring

Titration analyses are the cornerstone of physico-chemical monitoring in boiler rooms. They allow accurate measurement of structuring water parameters such as total hardness, partial alkalinity, total alkalinity, chlorides, sulfites, or CO₂.

Aqualabo provides the equipment required for these analyses: volumetric flasks, Erlenmeyer flasks, graduated cylinders, and various burettes suited to the volumes and titrant solutions used. Each parameter is linked to a titrant solution, a color indicator, and, when needed, clearly identified preparation reagents according to the relevant method.

These analyses make it possible to assess hardness, alkalinity, concentration, and water chemical balance, which are essential for managing blowdown, treatment programs, and preventing corrosion or scaling.

Colorimetric solutions for monitoring metals and treatment reagents

For parameters requiring quick and visual reading, especially in routine operation, Aqualabo offers colorimetric solutions suited to boiler room analysis.

Using the ORCHIDIS comparator, combined with dedicated cuvettes and specific colorimetric plates, enables control of sensitive parameters such as iron, dissolved oxygen, hydrazine, DEHA, manganese, phosphates, or silica.

These measurements are essential to monitor the effectiveness of corrosion-inhibitor treatments, detect early oxidation, or verify feedwater and condensate quality, without systematically relying on an external laboratory.

Single-parameter kits: simplicity and autonomy in the field

For routine checks or maintenance interventions, Aqualabo also offers complete, ready-to-use single-parameter kits.

These kits include all reagents, accessories, and protocols required to measure a targeted parameter autonomously, directly in the boiler room. They are particularly suited to technicians working across multiple sites or needing to perform frequent checks under operational conditions.

Aqualabo, partner to boiler room professionals

For maintenance technicians, installers, and plumbers, boiler water analysis makes it possible to understand circuit behavior, anticipate physico-chemical drift, and intervene in a targeted way before breakdowns, efficiency losses, or irreversible equipment degradation occur.

Aqualabo supports heating professionals with field-adapted analysis solutions. To define the most suitable analytical methods and equipment for your boiler room configuration, Aqualabo teams are available to help.