Water softener maintenance: hardness control and resin servicing

The correct adjustment of a water softener and regular maintenance of its resins directly affect the quality of the water distributed. For water treatment professionals, this is above all an essential control step to ensure the reliability of the installations. In this article, we will look at how measuring water hardness, checking settings, and maintaining resins can ensure long-lasting performance, prevent malfunctions, and guarantee water quality that meets field requirements.

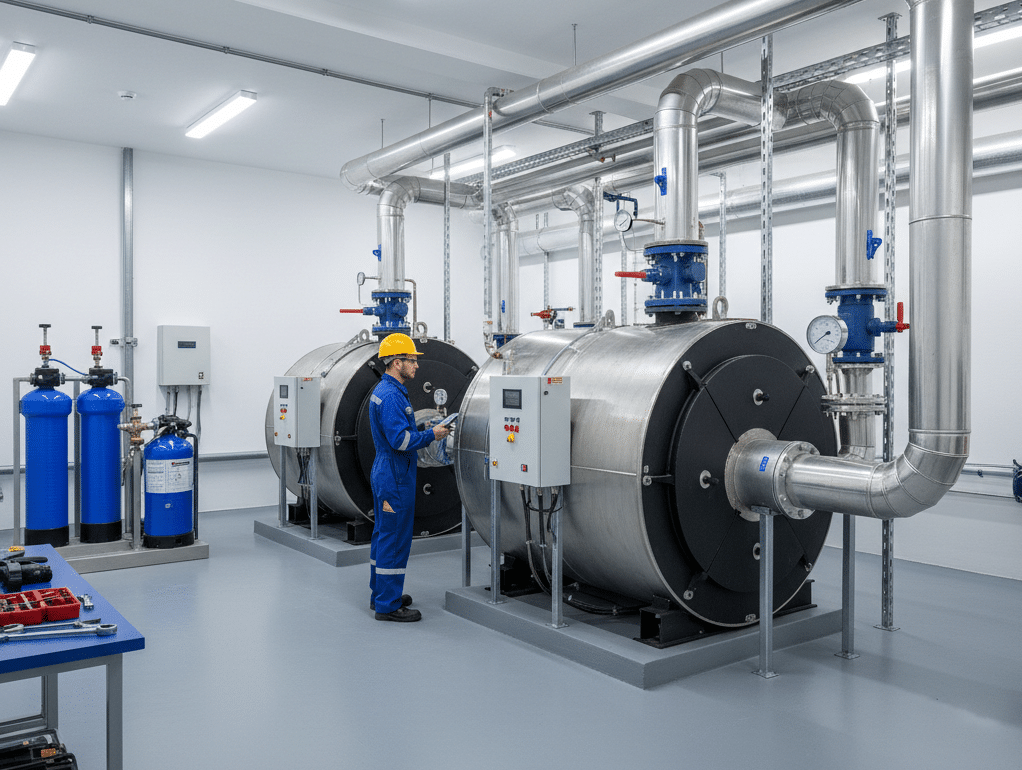

Adjusting and monitoring a water softener to ensure long-lasting performance

Understanding water hardness and its impact on installations

Water hardness corresponds to the concentration of calcium and magnesium ions, expressed in French degrees (°f). One degree corresponds to 10 mg/L of calcium carbonate.

Overly hard water promotes scale deposits in pipes, boilers and household appliances, resulting in increased energy consumption and premature wear. Conversely, water that is too soft can become aggressive, corroding metal pipes and fittings.

Principle of ion exchange and operation of water softeners

A water softener operates based on ion exchange: calcium (Ca²⁺) and magnesium (Mg²⁺) ions, responsible for hardness, are replaced with sodium (Na⁺) ions.

This process occurs within an ion-exchange resin contained in a tank. Over time, the resin becomes saturated and must be regenerated by flushing with brine.

System efficiency depends on proper regeneration and regular monitoring of settings, ensuring stable hardness at the softener outlet.

Hardness adjustment: ensuring softener performance

When commissioning a system, adjusting the residual hardness is a key step. The technician must ensure that the parameter settings deliver stable and compliant water. For optimal balance, the adjustment should fall between 7 and 10 °f. This threshold effectively protects against scaling while preventing corrosion.

Regular hardness checks at the softener outlet verify compliance with reference values and prevent deviations. For the technician, this monitoring is part of a quality approach: it ensures system performance, anticipates maintenance needs and reduces client callbacks. Documented hardness (TH) monitoring may also serve as proof of compliance for service contracts or quality audits.

Resin ageing and fouling: causes and prevention

Ion-exchange resins degrade over time due to several factors: mineral deposits, iron content, chlorine or the development of bacterial biofilms. These phenomena reduce exchange capacity and directly affect the softener’s efficiency. Strict monitoring therefore prevents loss of performance.

What are the risks of an improperly adjusted softener?

Incorrect parameter settings can disturb the chemical balance of water, potentially damaging metallic networks or causing abnormal salt consumption. They can also trigger inappropriate regeneration cycles, reducing the availability of treated water and increasing equipment wear.

For both users and professionals, poor adjustment often results in repeated malfunctions and reduced system reliability.

How to ensure proper monitoring of a water softener?

Checking hardness and precisely adjusting the softener after installation

Water hardness is easily checked using a hardness-test kit (TH kit). This colorimetric test allows rapid evaluation of calcium and magnesium levels before and after passage through the softener.

Once the measurement is taken, the technician adjusts the system settings to maintain compliant hardness. This verification must be included at each installation and repeated during maintenance visits.

Performing regular monitoring to maintain resin performance

Regular resin monitoring helps detect loss of exchange capacity and intervene before system efficiency declines.

During maintenance visits, the technician uses specific tools to check regeneration quality, assess resin condition and, when necessary, clean or replace them.

This preventive monitoring preserves exchange capacity, ensures consistent system performance and reduces the risk of corrective interventions.

On-site demonstration: proving softener efficiency to the client

Convincing a client in one minute with a before/after test

For sales teams, the demonstration case is an effective educational and commercial tool. It contains a functional mini-softener allowing live hardness testing: before and after passage through the resin.

One of the main advantages of the demonstration case lies in its ability to provide instant results. By testing the client’s water, then repeating the measurement after passage through the mini-softener, the technician obtains a clear and immediate comparison.

This visual approach is a decisive argument: the drop in TH is observable within seconds, with no need for complex technical explanations. For sales representatives, this rapid demonstration becomes an efficient lever to illustrate the concrete benefit of softening and facilitate decision-making.

Client case: reliable measurement tools to demonstrate installation performance

Context

Our client is a French company operating in the water-treatment sector. The company designs water softeners and handles installation and maintenance for private customers and small establishments such as restaurants.

During commercial actions or maintenance of installed equipment, the company required reliable measurement tools to demonstrate the efficiency of its systems.

Solutions

Our client provided its teams with demonstration cases including a functional mini-softener that can be easily connected to a tap to show the effectiveness of water treatment.

Before and after the demonstration, sales representatives perform a hardness test (TH) using kit 1KT004, clearly highlighting the performance of the ion-exchange resin.

Maintenance technicians also use these kits during interventions to verify water quality, clean the resins with our product (14DR03/7) or replace them when necessary.

AQUALABO solutions for professional monitoring and maintenance

Aqualabo instruments provide water-treatment professionals with a complete range of tools to effectively monitor softeners. Whether for one-off hardness checks, maintenance operations or client demonstrations, these devices facilitate the daily work of technicians and sales teams.

Drop-counting kits

Aqualabo hardness kits enable fast and reliable measurement of water hardness before and after softening.

Several models are available:

- Network-water TH kit (single bottle) – 1 drop = 1 °f – ref. ORMCD1003

- All-water TH kit (3 bottles) – 1 drop = 1 °f – ref. 1KT001

- Low-buffered-water TH kit (2 bottles) – 1 drop = 2 °f – ref. 1KT004

Analysis and demonstration cases

Aqualabo analysis cases bring together several essential tests for monitoring and presenting softener operation:

- TH hardness test (drop titration, 3 bottles: 2–60 °f)

- Calcium precipitation test

- Soap test

- Functional mini-softener (demonstration)

Some versions include a functional mini-softener, ideal for sales teams.

Custom cases can be designed upon request to meet company-specific needs.

Resin Cleaner (RESEN)

The RESEN softener-resin cleaner is a solution based on orthophosphoric acid specially formulated to remove deposits that reduce resin exchange capacity.

For preventive maintenance, once a year, a 250 mL dose should be used for a softener containing 10 to 20 L of resin before launching a manual regeneration.

Professional maintenance of water softeners

Aqualabo, an ISO 9001-certified company, designs and manufactures in France a complete range of instruments to support water-treatment professionals in their monitoring and maintenance operations.

To learn more about Aqualabo solutions dedicated to water-softener maintenance, hardness control and resin servicing, contact our teams for personalised support.